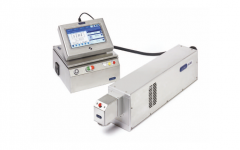

Linx FSL20 /FSL50 fibre laser coders

-

Linx FSL20 and FSL50 fibre laser coders offer a cost-efficient and hugely flexible coding solution across the widest range of materials and substrates for both static applications and moving production lines.

Key Benefits

- Fibre laser technology for permanent coding on a wide range of materials

- Fine spot size for high quality codes

- Codes large amount of information onto a small area

- Choice of 4 lenses for codes tailored to your requirements

- Compact marking head for easy integration into moving and static lines

- Air cooled for increased efficiency and less maintenance

- Laser tube life of over 100,000 hours.

Performance

- Line speed – 1 to 6,000 mm/s (typical). ·

- No of lines of text – Only limited by character size and marking field ·

- Character height – Up to marking field ·

- Print rotation – 0- 360 degrees ·

- Operation mode – pulsed (Q switch)

Physical Characteristics

- Material – Painted sheet metal housing ·

- Weight: marking unit/supply unit – 8kg / 19kg ·

- Laser head – IP54 ·

- Conduit length – 2.7m ·

- Minimum bend radius of conduit – 90 mm ·

- Head mounting options – 90-degree (standard) and straight-out (option) ·

- Cooling system – Air cooled with automatic overheat detection ·

- Supply voltage / frequency – Auto selection range 100 to 240 V / 50/60 Hz (auto range) ·

- Maximum power consumption – 500 VA ·

- Operating temperature range -10 – 40° C ambient ·

- Humidity range – 10% to 90% relative humidity, non-condensing

Marking Formats

- Standard fonts (Windows® TrueType®/TTF; PostScript®/PFA, PFB; OpenType®/OTF) ·

- Individual fonts such as high-speed or OCR ·

- Machine-readable codes: Bar codes: BC25,BC25I, BC39, BC93, EAN 8, EAN 13, BC128, EAN 128,Postnet, SCC14, UPC_A, UPC_E, RSS14TR, RSS14ST, RSS14STO, RSSLIM, RSSEXP Data matrix 2D codes: ECCOOO, ECC050, ECC080, ECC100, ECC140, ECC200, ECC PLAIN, QR ·

- Graphics/graphic components, logos, symbols, etc. (the most common file formats such as DXF, JPG,AI can be imported) ·

- Linear, circular, angular text marking; rotation, reflection, expansion, compression of marking contents ·

- Sequence & serial numbering; automatic date, layer, time coding, real-time clock; online coding ofindividual data (weight, contents, etc.)

Communication

- Ethernet, TCP/IP and RS232, digital I/Os ·

- Inputs for encoders and product detector triggers ·

- I/Os for start, stop, external error, job select, trigger, trigger enable, encoder, system ready, ready to mark, marking, shutter closed, error, bad, good signals and machine/ operator interlocks

-

Content coming soon